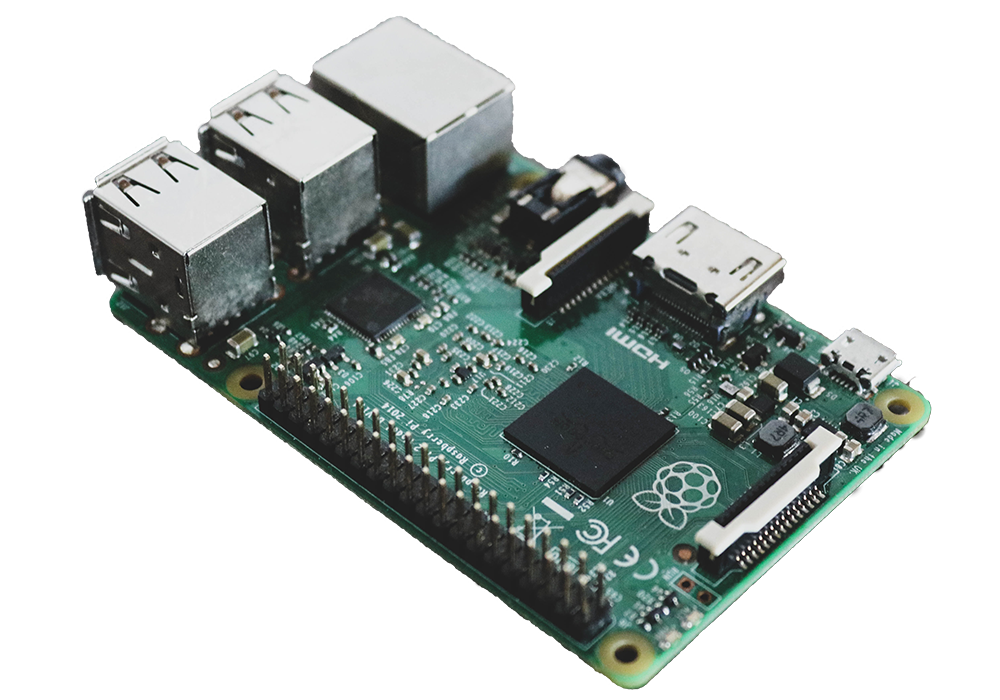

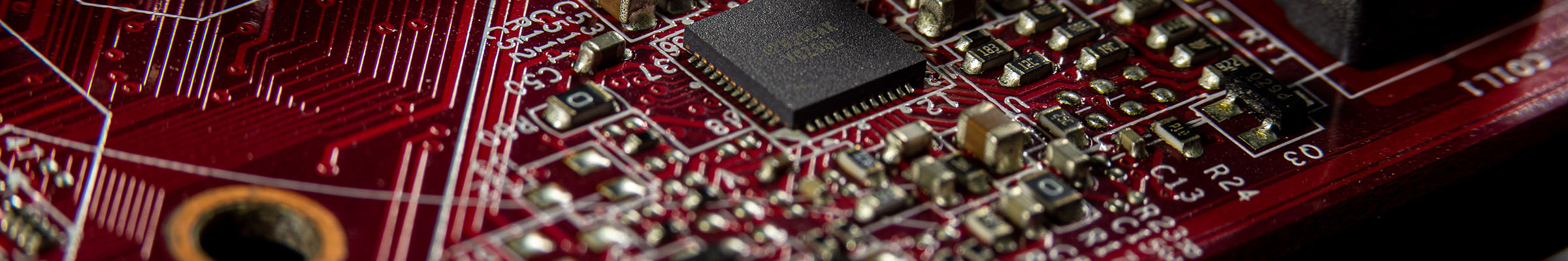

PCB Assembly

Cherrytech provides the very latest in PCB assembly and electronics manufacturing with facilities ranging from through-hole conventional assembly to the latest in surface mount µBGA, 0201 and fine pitch technology. Our fully trained colleagues work to the industry’s recognised standard of IPC-610 in a continuous improvement environment to provide quality assured products.

We are experienced in building products for all markets and have the facilities to assemble PCBs from the proto-type stage through to volume production.

To compliment our surface mount and leaded component assembly we inspect product using Automatic Optical Inspection and X-Ray equipment.

SMT Assembly:

Max Board size- 680 x 460mm

Component Placement size to 0201

BGA /uBGA

LGA

CSP

Forced Convection Reflow

ROHS compliant process

Non – ROHS (Leaded process) offered on request.

Proto-type assembly through to low and high volume assembly

Conventional Assembly:

Fully Automated Radial and Axial placement

Wave Solder

Hand Build.

Inspection:

Automatic Optical Inspection

X-Ray

Additional Capabilites:

Conformal Coating

Potting

Testing:

Functional Test

Diagnostics

If you want to contact us, please call +44 (0) 23 9223 1205 or Send us an email.